DARPA Cancels Cargo Seaplane Project, Focus to Dual-Use Tech

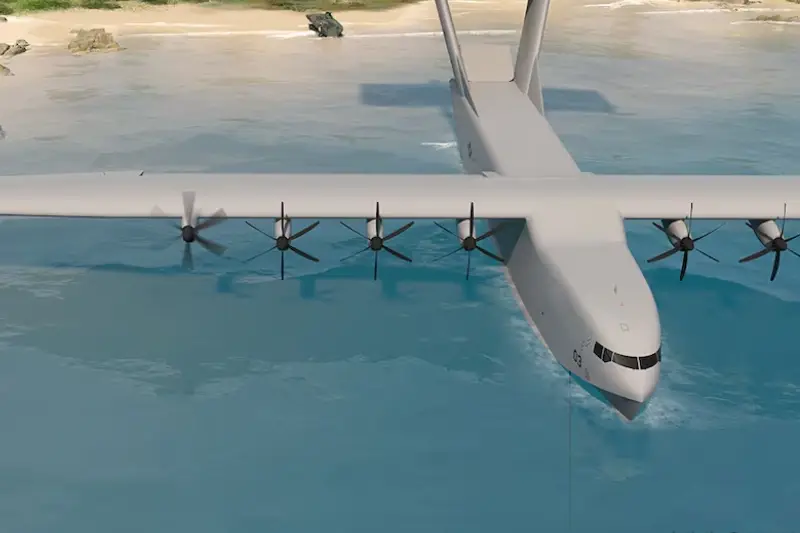

The Defense Advanced Research Projects Agency (DARPA) has ended an almost three-year experiment on developing a revolutionary heavy cargo seaplane called the Liberty Lifter program. Although the program is officially over, the technological improvements made in the course of the development process will certainly affect future manufacturing and design trends in the field of aircraft engineering within the military and civil aviation industries.

In June, DARPA asserted that the Liberty Lifter program was completed, as the more than three-year long experimental program to transform cargo transportation by developing seaplane technology came to an end. Developed with high aspirations of developing a long range low cost seaplane that would be able to operate in harsher seas, the program has proved to give many vital insights about aircraft manufacturing methods in the future.

Program manager Christopher Kent admitted the technical accomplishments of the program by saying that DARPA had discovered that they could construct a flying boat which could take off and land in high sea states. The science behind the concept was good, and the agency managed to show that aircraft could be well constructed by using the maritime construction methods and maritime composites.

Although the program was terminated, DARPA pointed out that Liberty Lifter project was able to prove its basic assumptions regarding the cost-efficient production of aircrafts. The agency showed that they could construct platforms that could fly much cheaper and be based on much more locations than achieveable with current plane capacity.

The findings of the program are opening the way to construction of next-generation aircraft with much more efficient manufacturing technologies. These insights would bring an impressive breakthrough in aerospace construction understanding in such a way that it may transform the aerospace manufacturing technology.

The Liberty Lifter program was intended to develop a seaplane having approximately similar abilities as that of the C-17 Globemaster capable of carrying an excess of 170,000 pounds of cargo comprising heavy machinery such as M1 Abrams tanks. This was a grand set of specs that was DARPA thinking in terms of an all purpose platform that could handle a large scale logistics operation in a tough maritime theatre.

The program was intended to foster new possibilities of military and commercial entities to perform rapid logistics operations as well as creating new manufacturing methods and materials. These two tasks were characteristic of DARPA with its focus on both dramatic capabilities and development of underlying technology.

An important goal of the program was aimed at inventing new manufacturing methods and materials to significantly lower the prices of manufacturing large aircraft. The Liberty Lifter project investigated the adaptation of maritime construction techniques to aircraft construction with a possibility of establishing more cost-effective manufacturing processes that could achieve future aviation platforms.

The work by DARPA into maritime composites and construction methodology was a break with conventional aircraft manufacturing avenues. The willingness of the agency to explore out-of-the-box manufacturing practices can be used to indicate its readiness to offer a profound solution to intricate engineering problems.

Its first partners were the General Atomics and Boeing subsidiary Aurora Flight Sciences, with the two companies coming up with rival concepts in the cargo seaplane. This competition strategy enabled DARPA to access various technical solutions in the process of maximising various industry capacities and skills.

Later in 2023, DARPA reorganized the Liberty Lifter program to more rapidly reduce technical risks. Such restructuring was a reflection of the adaptive style of the agency in managing its programs that could engage in strategic adaptations in line with arising technical knowledge and the needs of the programs.

Aurora and DARPA utilized full-scale modeling and simulating to show that the seaplanes technical design was viable. Such acts of validation were carried out by creating and testing prototypes of the new building techniques and materials that were to be used in the full-scale plane.

The tests and simulations were also effective in showing the technical feasibility of the Liberty Lifter concept and offered very important validation of the new manufacturing methods that were under consideration. This verification activity will assist in confirming that the technological developments realized on the program can be trusted to be applied on a long-term aircraft development project.

As Aurora Flight Sciences has said, the technology created in the course of the Liberty Lifter will be used in further aviation projects. The company is proud of technical advances that it has made during the preliminary design phase, and hopes to be able to use these lessons in future programs.

The statement by the company underlines the overall worth of the DARPA research strategy, which also implies that the research work carried out by them, even when the program is over, leads to newer technological breakthroughs that add value to the development processes in the future. This mode of technology transfer will make sure the investments in research can keep delivering value outside the program context originally associated with it.

DARPA admitted that further effort is required to integrate the maritime construction methods with the aircraft certification. This awareness underscores the fact that aviation manufacturing is regulated by a complex environment and that the scope of introducing new methods of construction in certified aircraft manufacture is not easy.

The certification issue poses a major setback to applying maritime construction in the aviation industry. This set of regulatory needs is critical to the deployment and unlocking the capacity of all the manufacturing innovations that have been created over the course of the Liberty Lifter program.

The Liberty Lifter program entailed contracts and changes of at least 22 million dollars, wherein 8 were distributed to General Atomics and 14 to Aurora Flight Sciences. This is the level of investment that illustrates that DARPA is committed to the exploration but is still responsible in matters of sustainable resource management.

The financial base of the program illustrates how DARPA has tried to manage technological risk by a diversated network of partnership and competitive development strategies. It is an investment perspective that permits an extensive exploration of creative ideas whilst retaining program responsibility.

DARPA is currently collaborating with industry partners and other players in the Defense Department to see how the technologies that were developed during the Liberty Lifter program can be rapidly deployed in other uses. This transition period is a vital milestone toward embodying that the technological breakthroughs in the program could have the broader implications and applications to the military and commercial aviation communities.

The agency interest in rapid technology fielding has been such that this is part of its mission of closing the gap that exists between research breakthroughs and the ability to attain an operative capability. Such a strategy allows guaranteeing that the research programs can produce innovating technologies and apply them soon, in practical applications, useful to both military and civilian populations.

Also read this: Lockheed Martin Delivers Advanced AN/SPY-7(V)1 Radars to Japan

Although the Liberty Lifter project has since ended without coming up with a demonstrator aircraft, the technological applications it provided shall perhaps have a significant impact in future aviation development endeavours. The marine construction process including cost effective methods of manufacturing that was educationally discussed in the program has provided new frontiers in designing and manufacturing planes.

The legacy of the program is shown in the fact that its innovative manufacturing techniques allowed large aircraft manufacturing to become cheaper and accessible. Such lessons will inevitably have an impact on the future aircraft development programs in both military and commercial aviation industry, making sure that the impact of the Liberty Lifter program would be much further than it was initially.

Keep connected with us at Facebook, Twitter, YouTube, Instagram & TikTok for latest defense happening around the globe.

Discover more from International Defence Analysis

Subscribe to get the latest posts sent to your email.